Tobacco Project

2025-03-08

|Successful Yonyou Implementation Cases

2025-03-08

|Successful Yonyou Implementation Cases

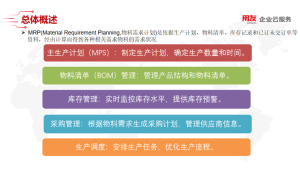

The MRP system enhances production efficiency, reduces inventory costs, and boosts customer satisfaction by optimizing material requirements planning and production processes. After implementation, companies achieve full automation and refined management in production, improving resource utilization, minimizing production delays, and optimizing inventory levels. Through real-time monitoring and precise scheduling, businesses can better respond to market changes, accelerate response times, and strengthen overall market competitiveness.

Overall Overview

Solution Value:

Implementation Results:

Implementation Results:

Inventory Turnover Rate Improvement**: By accurately planning material requirements and intelligent scheduling, inventory overstock is reduced, inventory turnover rates are increased, and liquidity and utilization of inventory are maximized.

Production Cost Reduction**: Through optimized inventory management and production processes, excess inventory and production downtime are minimized, unnecessary production costs are eliminated, and resource efficiency is enhanced.