Biochemical Engineering Project

2025-03-08

|Successful Yonyou Implementation Cases

2025-03-08

|Successful Yonyou Implementation Cases

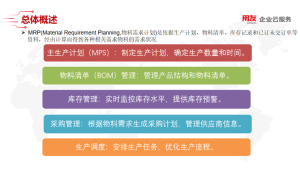

The MRP system enhances production efficiency, reduces inventory costs, and boosts customer satisfaction by optimizing material requirements planning and production processes. Post-implementation, companies achieve comprehensive automation and refined production management, improving resource utilization, minimizing production delays, and optimizing inventory levels. Real-time monitoring and precise scheduling enable businesses to better respond to market changes, enhance responsiveness, and strengthen overall market competitiveness.

Overall Summary:

方案价值

实施成果

1.库存周转率提升:通过精准的物料需求计划和智能调度,有效减少库存积压,提高库存周转率,确保资金流动性和库存利用率的最大化。

2.生产成本降低:通过优化库存

The MRP system optimizes management and production processes by reducing excess inventory, production stoppages, and interruptions, thereby lowering unnecessary production costs and improving resource utilization.

Improved Production Efficiency: Through refined production planning and process optimization, the system achieves rational allocation of production resources, enhances operational smoothness and efficiency, and shortens production cycles.

High Degree of Automation: By integrating advanced automation systems, the solution minimizes manual intervention and human error, boosts work efficiency, reduces labor intensity, and ensures precise and efficient production processes.